| Availability: | |

|---|---|

| Quantity: | |

YUFFEN

Product Name | High Temperature Single Sided Polyimide Film Tape |

Kind | Single Sided Pi strip |

Color | Amber/Brown/Gold |

Thickness | 0.6mm |

Temperature resistance | 200-300°C |

Personalized service | Slitting/Die cutting |

OEMs and OBMs | Support |

Sample | A4 size free sample |

Application | 1. In the SMT process, the thermocouple wire should be stuck when measuring the temperature of the reflux oven. 2. In SMT process, it is used to stick the flexible printed circuit (FPC) on the fixture, to do a series of processes such as printing, patching and testing. 3. It can be wrapped on the cable and used as insulating tape. 4. It can be pasted on the connector to pick up materials by the fitter, so as to replace the iron sheet. 5. It can be cut into any other shape for special purpose. |

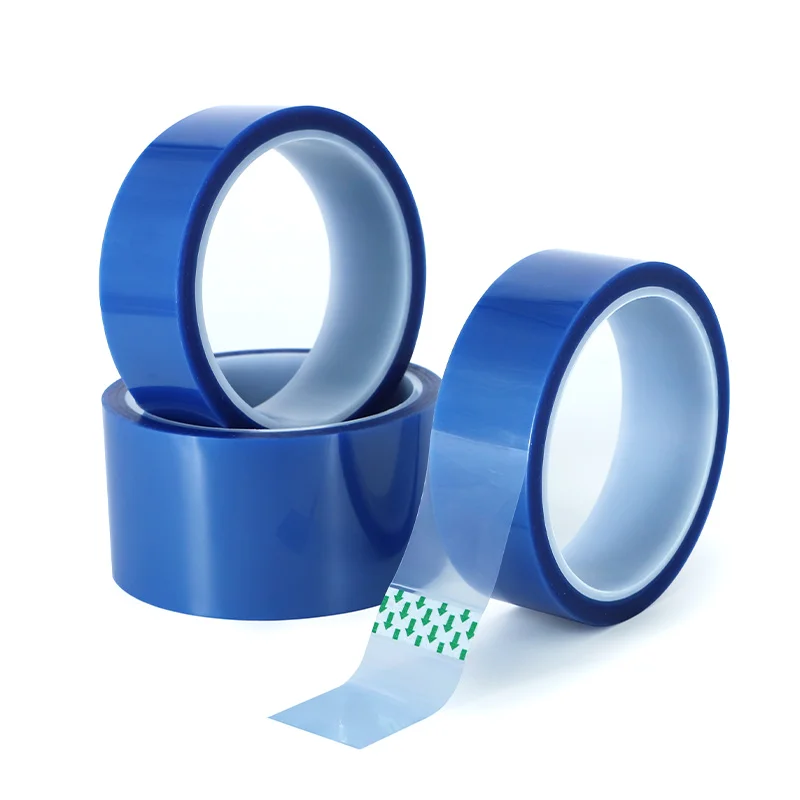

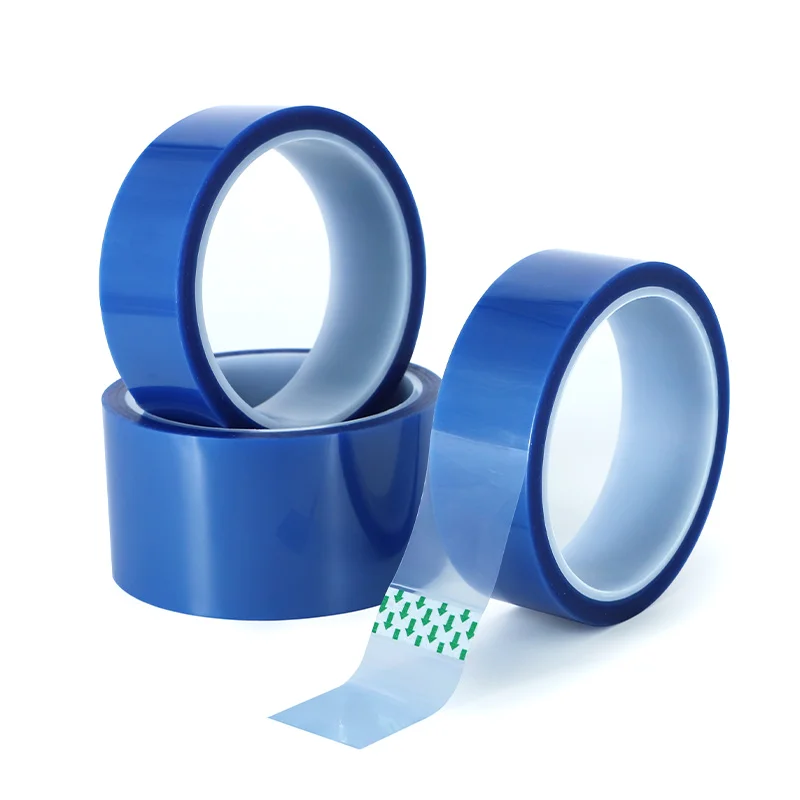

In order to keep up with the pace of new energy vehicle manufacturing, we’ve been developing series of EV battery tapes and protective films, like Battery tab tape, Termination tape, BOPP protective film, PET Protective film,etc.

Our low adhesion Polyester film tape provide protection during transportation of EV battery, and also provide protection during the bar code printing

Product Name | High Temperature Single Sided Polyimide Film Tape |

Kind | Single Sided Pi strip |

Color | Amber/Brown/Gold |

Thickness | 0.6mm |

Temperature resistance | 200-300°C |

Personalized service | Slitting/Die cutting |

OEMs and OBMs | Support |

Sample | A4 size free sample |

Application | 1. In the SMT process, the thermocouple wire should be stuck when measuring the temperature of the reflux oven. 2. In SMT process, it is used to stick the flexible printed circuit (FPC) on the fixture, to do a series of processes such as printing, patching and testing. 3. It can be wrapped on the cable and used as insulating tape. 4. It can be pasted on the connector to pick up materials by the fitter, so as to replace the iron sheet. 5. It can be cut into any other shape for special purpose. |

In order to keep up with the pace of new energy vehicle manufacturing, we’ve been developing series of EV battery tapes and protective films, like Battery tab tape, Termination tape, BOPP protective film, PET Protective film,etc.

Our low adhesion Polyester film tape provide protection during transportation of EV battery, and also provide protection during the bar code printing

1.Special Polypropylene film as carrier

2.Thickness with 0.055mm, 0.07mm, 0.085mm

3.Low acrylic adhesion

4.Anti acid and alkaline acrylic adhesive

5.High temperature resistance to 130℃

6.Very easy to peel off without residue and pollution to battery

7.Halogen content meet the IEC 61249-2-21 and EN – 14582 battery requirements

8.Protect the battery during transportation

9.Protect the battery during bar code printing and battery processing

1.Special Polypropylene film as carrier

2.Thickness with 0.055mm, 0.07mm, 0.085mm

3.Low acrylic adhesion

4.Anti acid and alkaline acrylic adhesive

5.High temperature resistance to 130℃

6.Very easy to peel off without residue and pollution to battery

7.Halogen content meet the IEC 61249-2-21 and EN – 14582 battery requirements

8.Protect the battery during transportation

9.Protect the battery during bar code printing and battery processing

Applications

In order to To save energy and reduce emissions, over the past decade, electric vehicles (EVs) have become more and more popular in the automotive market. And all the EV Manufacturer focus on the battery production, and the EV battery need to be properly secured and encapsulated by using special materials to reduce the flammability, increase dielectric strength, and provide protection from adverse environmental conditions.

Applications

In order to To save energy and reduce emissions, over the past decade, electric vehicles (EVs) have become more and more popular in the automotive market. And all the EV Manufacturer focus on the battery production, and the EV battery need to be properly secured and encapsulated by using special materials to reduce the flammability, increase dielectric strength, and provide protection from adverse environmental conditions.