Views: 0 Author: Site Editor Publish Time: 2024-05-10 Origin: JIANGYIN YUFFEN ELECTRONICS CO., LTD.

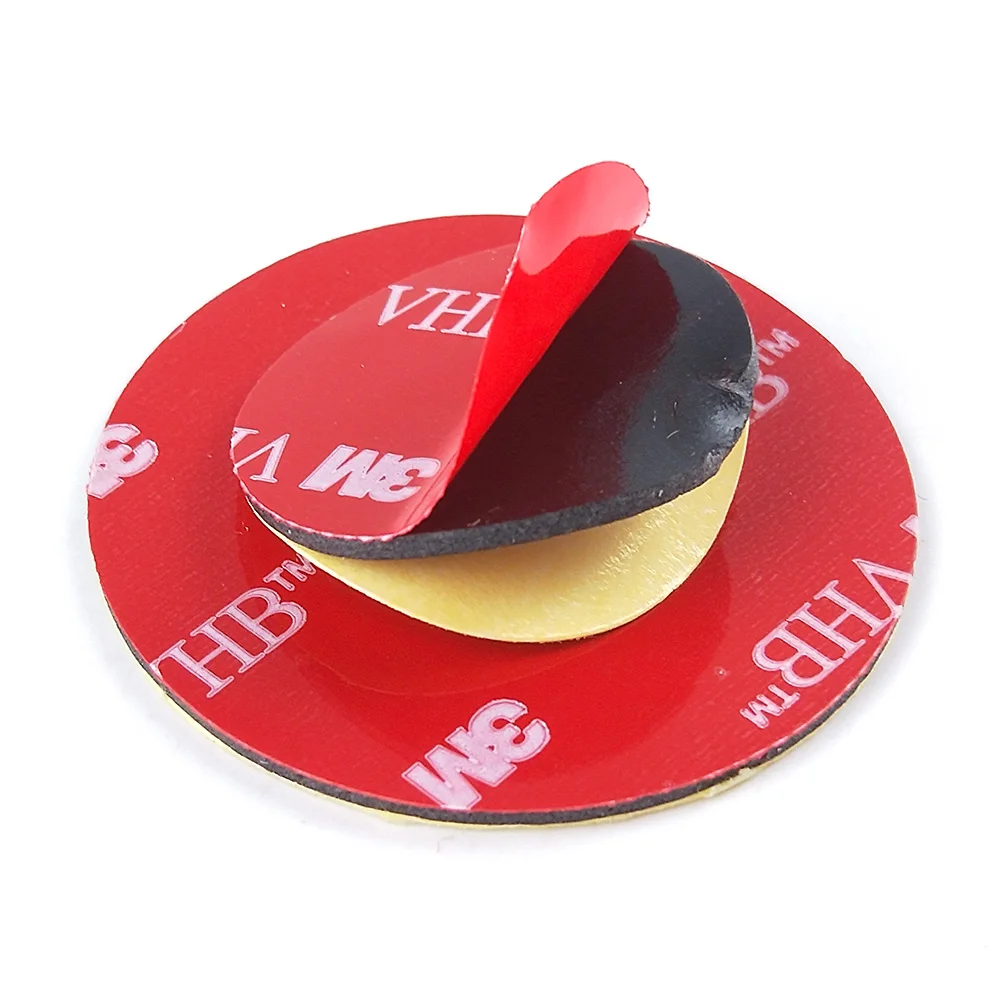

Correct pasting of 3M double-sided tape can achieve the best pasting effect, in some not very smooth walls or adhesive surfaces, can not be completely fitted, can not achieve a good bonding effect. Therefore, it is necessary to master the correct bonding method of 3M double-sided tape in order to get twice the result with half the effort.

The first step: the adhesive surface must be cleaned and boring, usually advocate a cloth dipped in a mixture of 1:1 IPA (isopropyl alcohol) and water for surface wipe cleaning, and then the appearance is completely dry.

Step 2: After the cleaning solvent is dry, the tape is applied to the adhesive surface and a pressure of about 15PSI (1.05 kg/cm²) is applied by a roller or other method to make it effectively bonded.

Step 3: Remove the adhesive release liner and apply the same 15PSI pressure to the adhesive material to make it fit effectively. If air bubbles need to be removed, the pressure should be increased to the maximum acceptable limit of the item.

Step 4: Post your ambition at a temperature of 15-38°C and not lower than 10°C.

Step 5: When adhesive tape is bonded, one end should be laminated first, and then slowly pressed to the other end to reduce the chance of air bubbles.